Our Proven Process

Understanding the "why" behind our methods.

Powder coating is a high-quality dry finishing process. Unlike traditional liquid paint, it is a fine, dry powder applied to a metal surface, melted under heat, and fused into a protective layer. The result is a uniform, durable, and attractive finish that is far superior to conventional paint.

The 3 Steps to a Perfect Finish

1. Pre-Treatment

The foundation of a perfect finish. This multi-stage chemical process ensures the metal is surgically clean. It includes:

• Degreasing: To remove all oils.

• Conversion Coating: A crucial step that acts like a super-glue primer, ensuring maximum adhesion.

• Rinsing: Pure water rinses leave the surface absolutely spotless.

2. Powder Application

Using an electrostatic spray gun, we apply a positive charge (+) to the powder. The grounded metal part (-) acts like a magnet, pulling the powder to it for a perfectly even coat, with no drips or runs.

3. Curing

The part is heated in a curing oven. The heat melts and fuses the powder into a single, hard, non-porous skin. This chemical reaction creates a finish that is far more durable than traditional paint.

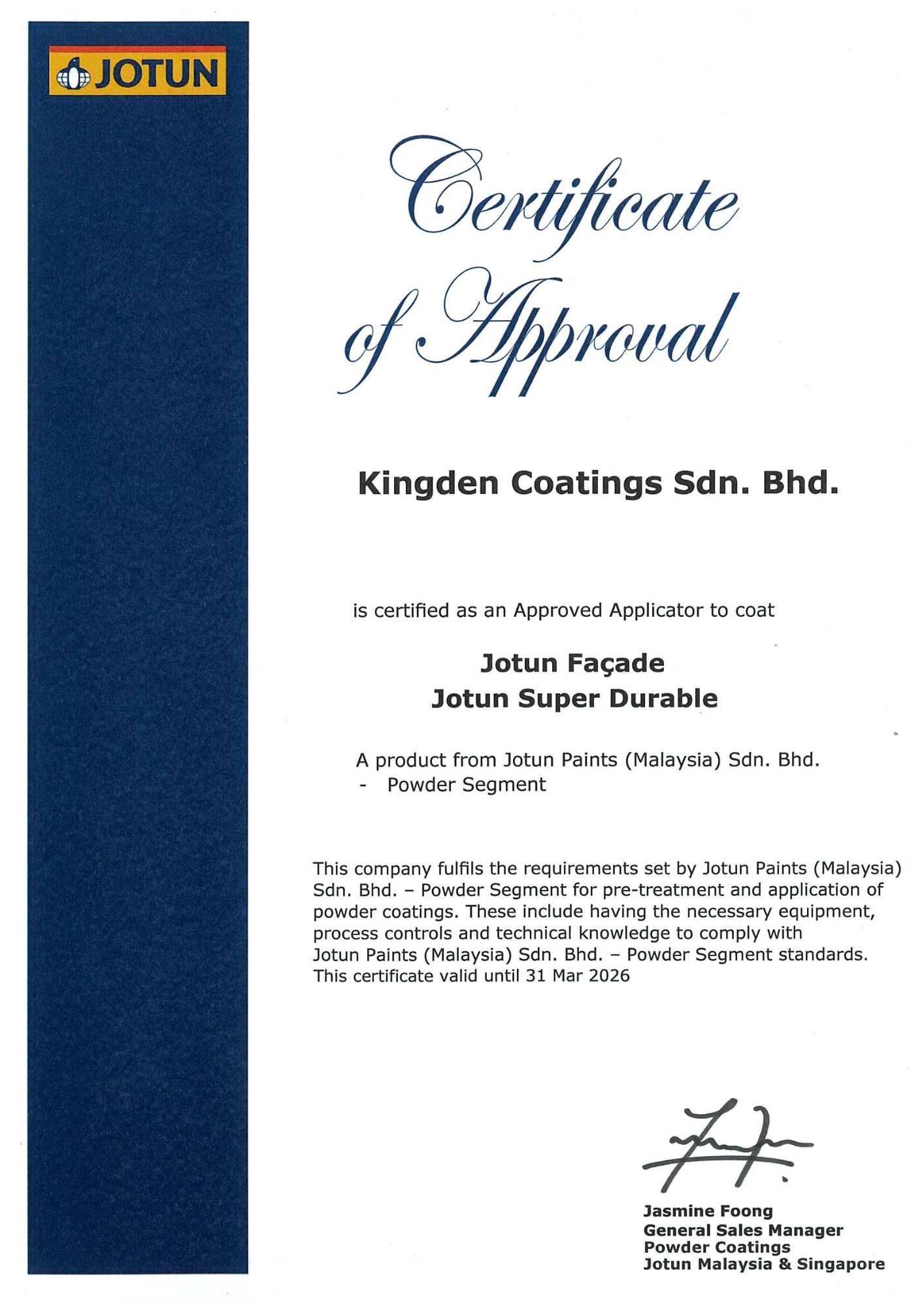

Our Qualifications

We are certified and approved applicators for the industry's most trusted brands. You can also click to view the full document.

The Kingden Advantage

The process is the science. The execution is the art. Here’s why our approach is different.

Premium Materials

We exclusively use globally-recognized powders from our approved partners, ensuring superior performance.

Meticulous Preparation

We believe a perfect finish starts with perfect prep. Our multi-stage chemical treatment is a critical, uncompromised step in our workflow.

Expert Technicians

Our team is highly trained in the art of electrostatic application, guaranteeing a flawless, even coat on every project, every time.

Powder Coating vs. Conventional Paint

| Feature | ✔ Powder Coating (Our Method) | ❌ Conventional Paint |

|---|---|---|

| Durability | Extremely resistant to chipping, scratching, and fading. Forms a hard, protective skin. | Prone to chipping and flaking. Requires more frequent touch-ups and repainting. |

| Finish Quality | Creates a thick, perfectly uniform coating with no drips, runs, or sags. | Thinner coats can lead to drips and inconsistencies. Can be difficult to apply evenly. |

| Environmental Impact | Contains no solvents and releases zero/negligible VOCs. Overspray can be recycled, creating almost no waste. | Releases VOCs into the atmosphere. More waste produced from overspray and cleaning. |

| Long-Term Value | Higher initial investment, but far more cost-effective over time due to superior longevity and low maintenance. | Lower upfront cost, but leads to higher long-term costs from maintenance and repainting cycles. |

Experience the Difference

See how our commitment to quality translates into stunning results, or contact us to discuss your project today.